Compare Product Specifications (2026)

Master product specification comparison with proven strategies for vendor proposals and technical documents. Step-by-step guide for procurement teams.

SpecLens Team

Procurement & AI Experts

Why Product Specification Comparison Matters

In today's competitive procurement landscape, making the right purchasing decision can mean the difference between project success and costly mistakes. Whether you're procuring equipment, materials, or IT infrastructure, comparing product specifications accurately is crucial.

According to industry research, procurement teams spend an average of 15-20 hours per week comparing vendor proposals and specifications. Yet, despite this time investment, manual comparison methods lead to:

- 30-40% error rate in specification extraction

- Missed key differences between competing products

- Delayed purchasing decisions due to information overload

- Higher costs from suboptimal vendor selection

The Challenge of Manual Comparison

Traditional specification comparison methods present several challenges:

1. Document Format Variability

Vendors submit proposals in different formats—PDFs, Word documents, Excel spreadsheets, PowerPoint decks, and webpages/HTML. Each format requires a different approach to extract and compare data, making the process time-consuming and error-prone.

2. Inconsistent Terminology

Different vendors use different terms for the same specifications. One might list "maximum operating temperature," while another uses "thermal limit" or "temperature range." This inconsistency makes side-by-side comparison difficult.

3. Hidden Specifications

Critical specifications are often buried in technical appendices, footnotes, or separate documents. Manual review can easily overlook these details, leading to incomplete comparisons.

A Systematic Approach to Specification Comparison

Here's a proven 7-step framework for effective product specification comparison:

Step 1: Define Your Requirements

Before comparing any specifications, clearly document your requirements:

- Must-have specifications: Non-negotiable requirements that products must meet

- Nice-to-have features: Desirable but not essential attributes

- Deal-breakers: Specifications or features that would disqualify a product

- Budget constraints: Maximum price points and total cost of ownership

Pro Tip: Create a requirements matrix before requesting proposals. This ensures all vendors provide information in a comparable format.

Step 2: Standardize Your Comparison Criteria

Develop a standard set of criteria for evaluation:

- Technical specifications (performance, capacity, dimensions)

- Compliance certifications (ISO, CE, UL, etc.)

- Environmental factors (operating temperature, humidity, power consumption)

- Warranty and support terms

- Delivery timeline and lead times

- Total cost of ownership (purchase price + operating costs)

Step 3: Extract Specifications Systematically

Use a consistent method to extract specifications from each vendor document:

- Create a template: Build a spreadsheet or table with all comparison criteria

- Read thoroughly: Don't skip technical appendices or fine print

- Normalize units: Convert all measurements to standard units (metric or imperial)

- Flag missing data: Note when vendors don't provide required specifications

- Document assumptions: Record any interpretations or estimated values

Step 4: Identify Specification Gaps

Look for missing or incomplete information:

- Specifications that one vendor provides but others don't

- Vague or ambiguous terminology

- Specifications that require clarification or additional documentation

Contact vendors to fill these gaps before making comparisons. Incomplete data leads to uninformed decisions.

Step 5: Perform Apples-to-Apples Comparison

Now that you have standardized data, compare products fairly:

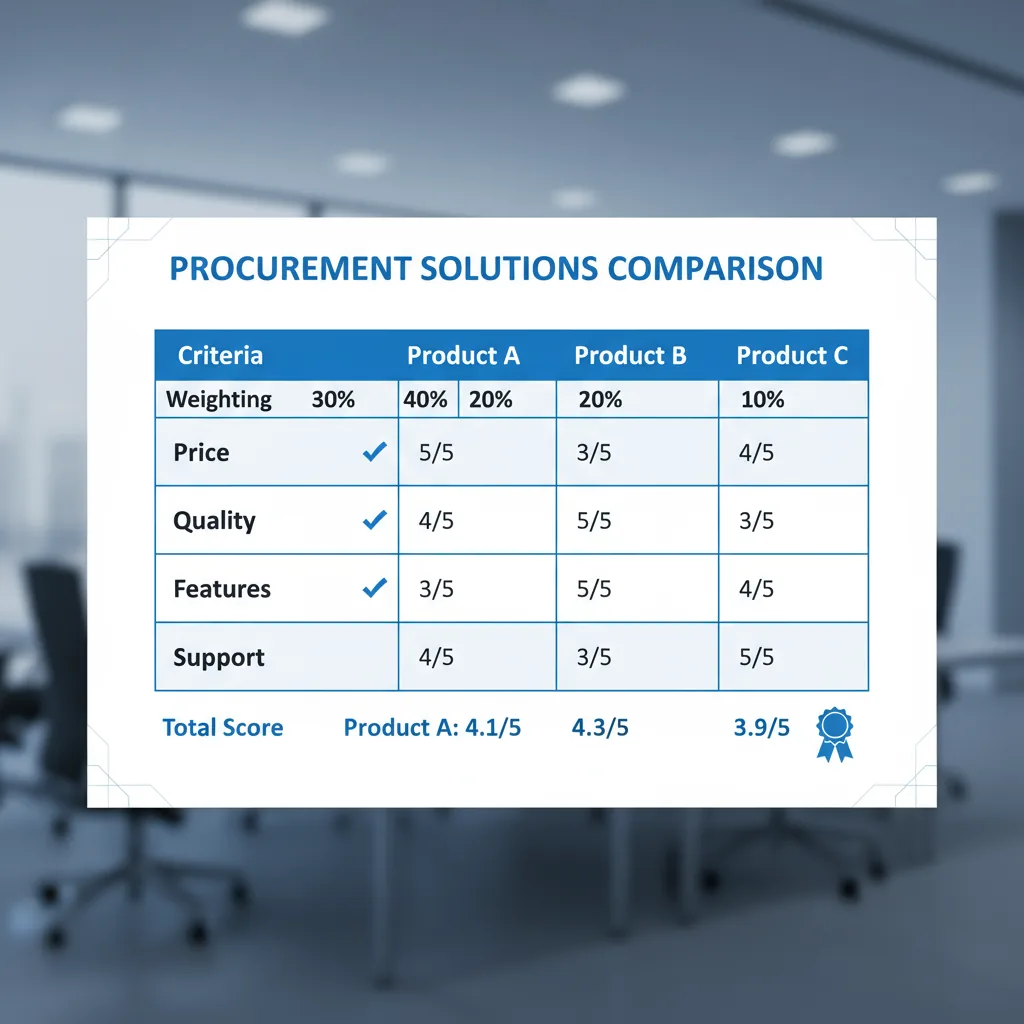

- Use visual aids: Create comparison tables, charts, or graphs

- Highlight differences: Make it easy to spot variations between products

- Score objectively: Use weighted scoring if you have multiple criteria

- Consider context: A "better" specification isn't always necessary for your use case

Step 6: Calculate Total Cost of Ownership (TCO)

Don't just compare purchase prices. Consider the full lifecycle costs:

- Initial purchase price

- Installation and setup costs

- Operating costs (energy, consumables, maintenance)

- Training requirements

- Expected lifespan

- Disposal or recycling costs

A product with a higher upfront cost might have lower operating expenses, making it more economical over its lifetime. Use our TCO Calculator to compare lifecycle costs, and see our complete TCO Calculator Guide for a step-by-step methodology with industry examples.

Step 7: Document Your Analysis

Create a comprehensive comparison report that includes:

- Executive summary with key findings

- Detailed specification comparison table

- Analysis of strengths and weaknesses for each product

- TCO calculations

- Risk assessment

- Final recommendation with justification

This documentation is invaluable for stakeholder approval and future reference.

Common Pitfalls to Avoid

1. Focusing Only on Price

The cheapest option is rarely the best long-term value. Consider quality, reliability, support, and TCO.

2. Ignoring Vendor Reputation

Specifications on paper don't guarantee real-world performance. Research vendor track records, customer reviews, and case studies. Strong vendor relationships also improve your position in negotiating better terms.

3. Over-Specifying Requirements

Requiring the highest specifications for every criterion can unnecessarily limit your options and increase costs. Distinguish between "must-haves" and "nice-to-haves."

4. Not Involving Stakeholders

Procurement decisions affect multiple departments. Involve end users, technical teams, and management early in the process.

5. Rushing the Analysis

Thorough specification comparison takes time. Rushing leads to errors and suboptimal decisions that cost more in the long run.

How AI is Transforming Specification Comparison

Modern AI-powered tools are revolutionizing how procurement teams compare specifications:

- Automated extraction: AI reads PDFs, Word docs, and spreadsheets, extracting specifications automatically

- Intelligent normalization: Converts different units and terminology to standardized formats

- Gap detection: Identifies missing specifications and inconsistencies

- Visual comparisons: Generates side-by-side comparison tables instantly

- Time savings: Reduces comparison time from hours to minutes

Tools like SpecLens can process multiple vendor documents simultaneously, creating comprehensive comparison matrices in seconds. This allows procurement teams to focus on analysis and decision-making rather than manual data entry. Explore how SpecLens works.

Best Practices for Procurement Teams

1. Create Standard Templates

Develop RFP templates that request specifications in a standardized format. This makes comparison much easier.

2. Build a Specification Database

Maintain a database of past comparisons. This historical data helps benchmark new proposals and identify pricing trends.

3. Invest in Training

Ensure your team understands technical specifications, industry standards, and comparison methodologies.

4. Use Collaborative Tools

Cloud-based comparison tools allow multiple team members to review and comment on specifications simultaneously.

5. Continuously Improve

After each procurement cycle, conduct a retrospective. What worked? What didn't? How can the process improve?

Industry-Specific Considerations

Manufacturing & Industrial Equipment

Focus on durability, maintenance requirements, spare parts availability, and compliance with safety standards.

IT & Technology Procurement

Prioritize compatibility, scalability, security certifications, and vendor support lifecycles.

Construction Materials

Emphasize material certifications, environmental ratings, delivery logistics, and project-specific requirements.

Healthcare Equipment

Regulatory compliance (FDA, CE), sterilization compatibility, and patient safety are paramount.

Measuring Comparison Success

Track these metrics to evaluate your specification comparison process:

- Time to decision: How long from receiving proposals to making a selection?

- Decision confidence: Are stakeholders confident in the chosen product?

- Post-purchase satisfaction: Does the product meet expectations?

- Cost accuracy: Were TCO estimates accurate?

- Process efficiency: How much effort was required for comparison?

Conclusion

Generate Your Specification Checklist

Create a comprehensive, AI-powered checklist for any product category. Ensure you never miss critical specifications during vendor evaluation.

Generate Checklist Free →Effective product specification comparison is both an art and a science. It requires systematic methodology, attention to detail, and the right tools. By following this guide's framework—defining requirements, standardizing criteria, extracting specifications systematically, and calculating total cost of ownership—your procurement team can make better decisions faster.

The future of specification comparison lies in AI-powered automation. Tools that can read vendor documents, extract specifications, normalize data, and generate comparison matrices will become essential for competitive procurement teams.

Whether you're comparing equipment, materials, IT infrastructure, or services, the principles remain the same: be thorough, be systematic, and focus on value, not just price.

Ready to transform your specification comparison process? Try SpecLens and experience AI-powered comparison that saves time and reduces errors. Start your free trial today, or explore all our free procurement tools.

Tags:

Related Articles

How to Write an RFP: 2026 Guide

Complete RFP writing guide for 2026. Learn the 10 essential components, step-by-step process, and templates that get quality vendor responses.

Free TCO Calculator + Complete Guide (2026)

Use our free TCO calculator to compare vendor costs. Includes the TCO formula, hidden cost checklist, and real industry examples.

Vendor Negotiation: 6 Strategies for 2026

Negotiate better deals with suppliers using these 6 proven strategies. Save costs, secure better terms, and build stronger vendor relationships.

5 Procurement Best Practices for 2026

Stay ahead of the curve with these essential procurement best practices. From digital transformation to sustainability, learn how to modernize your sourcing.