Reduce Procurement Cycle Time

Learn proven strategies to reduce procurement cycle time without sacrificing quality. Identify bottlenecks and accelerate selection.

SpecLens Team

Procurement & AI Experts

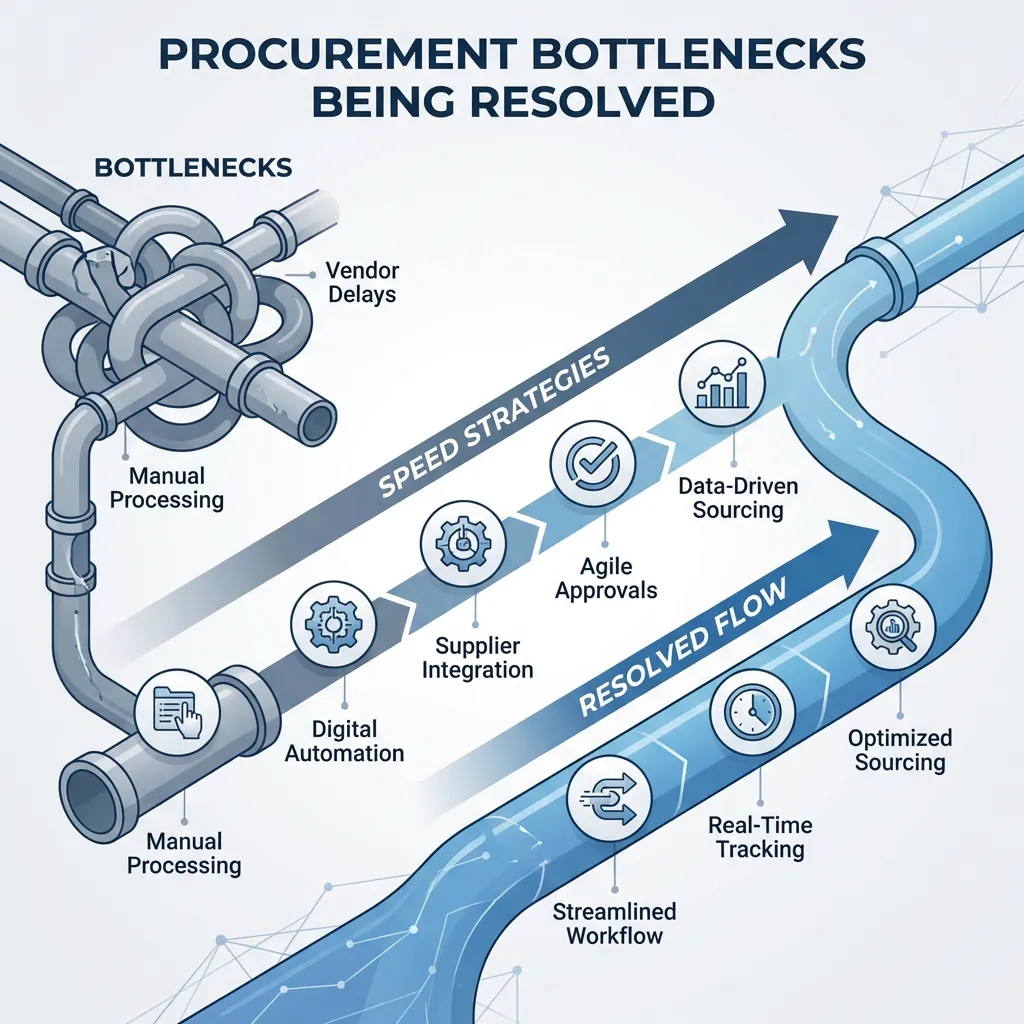

Procurement cycles are too slow. Stakeholders complain about delays. Business opportunities slip away while you're still evaluating vendors. But rushing procurement creates different problems—bad vendor choices and regrettable contracts.

This guide shows you how to reduce procurement cycle time without sacrificing decision quality—identifying bottlenecks, implementing proven solutions, and building sustainable improvements.

Why Cycle Time Matters

| Impact | Consequence |

|---|---|

| Project delays | Revenue impact, market timing |

| Opportunity cost | Business waiting for decisions |

| Resource waste | Staff time on extended processes |

| Stakeholder friction | Frustration, workarounds |

| Compliance pressure | Rushed decisions at the end |

Typical Cycle Time Breakdown

| Phase | Activities | Typical Duration |

|---|---|---|

| Requirements | Define needs, specifications | 2-6 weeks |

| Sourcing | Identify vendors, issue RFP | 2-4 weeks |

| Response period | Vendors prepare responses | 2-4 weeks |

| Evaluation | Compare vendors, select winner | 2-6 weeks |

| Negotiation | Finalize terms and contract | 2-4 weeks |

| Approval | Internal approvals, signatures | 1-4 weeks |

| Total | 11-28 weeks |

Identifying Bottlenecks

| Bottleneck | Typical Cause | Symptom |

|---|---|---|

| Requirements definition | Unclear needs, stakeholder disagreement | Multiple revisions |

| Response analysis | Manual comparison, many vendors | Weeks of document review |

| Internal alignment | Many stakeholders, different priorities | Circular discussions |

| Approval layers | Multiple sign-offs, absent approvers | Documents in queues |

| Legal review | Complex terms, risk aversion | Weeks of back-and-forth |

Key Insight: Queue time vs. touch time—often the biggest opportunity. Documents may take 2 days of work spread over 3 weeks due to waiting.

Quick Wins: Immediate Improvements

Parallel Processing

| Instead Of | Do This |

|---|---|

| Write requirements → then identify vendors | Research vendors while defining requirements |

| Complete technical eval → then start commercial | Evaluate technical and commercial in parallel |

| One approval → then next → then next | Parallel approval routing when possible |

| Wait for all responses → then start analysis | Begin analyzing as responses arrive |

Template Standardization

| Template | Time Saved |

|---|---|

| Standard RFP structure | 40-60% of RFP development |

| Evaluation criteria | 50-70% of criteria development |

| Common specifications | 30-50% of spec writing |

| Contract templates | 60-80% of legal drafting |

Technology-Enabled Acceleration

Automated Specification Comparison

| Manual Approach | AI-Powered Approach |

|---|---|

| Read each document | Upload all documents |

| Extract specifications manually | Automatic extraction |

| Create spreadsheet | Comparison matrix generated |

| Normalize units | Automatic normalization |

| Time: 4-8 hours/vendor | Time: 15-30 minutes total |

⏱️ Parallel vs. Serial Approval

Serial: Buyer → Manager (2 days) → Legal (5 days) → Security (5 days) → Finance (2 days) = 15 days

Parallel: Buyer → [Legal + Security + Finance simultaneously] = 5 days

Process Redesign

Simplify Evaluation Criteria

| Simplification | Impact |

|---|---|

| Fewer criteria | Faster evaluation, clearer decisions |

| Binary for must-haves | Quick pass/fail determination |

| Focus on differentiators | Skip evaluation of identical specs |

Right-Size the Process

| Purchase Type | Process Complexity |

|---|---|

| Routine, low-risk | Simplified, minimal approvals |

| Moderate value/risk | Standard process |

| Strategic, high-value | Full process with stakeholders |

| Emergency | Expedited with post-review |

The Pre-Approved Catalog Strategy

The fastest cycle time is zero. Build a catalog of pre-approved items:

- "If it's in the catalog and under $1k, auto-approve"

- "If it's off-catalog, full cycle"

- Result: Removes 40% of volume from approval queue

Measuring Improvement

| Metric | Target Direction |

|---|---|

| Total cycle time | Reduce |

| Time per phase | Identify problem phases |

| Queue time | Minimize |

| First-pass approval rate | Increase |

| Rework percentage | Decrease |

Frequently Asked Questions

How much cycle time reduction is achievable?

Organizations typically achieve 30-50% reduction through process improvements. Technology-enabled improvements can add another 20-30% for specific bottlenecks like document analysis.

Should we sacrifice quality for speed?

No. The goal is removing waste and delays, not skipping important steps. Well-designed processes are both faster and higher quality than poorly-designed ones.

What if stakeholders resist faster timelines?

Show how current delays create business risk. Involve resistant stakeholders in process design. Demonstrate that better process—not shortcuts—enables speed.

Speed Up Specification Comparison

SpecLens eliminates the manual bottleneck of document comparison—turning hours of work into minutes.

Try SpecLens Now →Speed Up Without Sacrificing Quality

Procurement cycle time reduction isn't about rushing—it's about eliminating waste, parallelizing work, and using better tools.

Tags:

Related Articles

The True Cost of Manual Procurement

Manual processes are bleeding your budget. We analyze the hidden costs of human error, slow processing, and employee burnout.

5 Procurement Best Practices for 2026

Stay ahead of the curve with these essential procurement best practices. From digital transformation to sustainability, learn how to modernize your sourcing.

Procurement Burnout: Hidden Costs

Manual specification review is burning out your procurement team. Discover the numbers behind the silent epidemic and how AI can help reclaim your team's time.

Procurement Automation ROI Guide

Learn how to calculate procurement automation ROI. Build a business case with metrics for time savings and error reduction.