Construction Equipment Buying Guide

Navigate construction equipment procurement confidently. Learn heavy equipment specs, buy vs rent analysis, and vendor comparison.

SpecLens Team

Procurement & AI Experts

Construction equipment represents significant capital investment with direct impact on project productivity and profitability. The right equipment enables efficient operations. The wrong equipment undermines project economics and creates downstream problems.

This guide covers what construction buyers need to know when procuring heavy equipment—from evaluation through acquisition and lifecycle management.

Why Construction Equipment Decisions Matter

The Financial Impact

| Equipment Type | Typical Price Range |

|---|---|

| Compact excavators | $30,000 - $100,000 |

| Standard excavators | $100,000 - $500,000+ |

| Wheel loaders | $100,000 - $400,000+ |

| Dozers | $150,000 - $750,000+ |

| Mobile cranes | $200,000 - $2,000,000+ |

| Tower cranes | $300,000 - $1,500,000+ |

Project Productivity Impact

| Equipment Factor | Project Impact |

|---|---|

| Underpowered equipment | Slower cycle times, delayed completion |

| Oversized equipment | Wasted capital, higher operating costs |

| Poor reliability | Downtime, schedule disruption |

| Mismatched capability | Workarounds, reduced efficiency |

| Inadequate capacity | Bottlenecks, resource constraints |

Key Insight: The difference between optimal and suboptimal equipment can be 20-40% productivity variance.

Equipment Categories

Earthmoving Equipment

| Equipment | Primary Use | Key Specifications |

|---|---|---|

| Excavators | Digging, trenching, loading | Dig depth, reach, bucket capacity |

| Bulldozers | Grading, pushing, clearing | Blade width, horsepower |

| Wheel loaders | Loading, carrying | Bucket capacity, lift height |

| Graders | Fine grading, road building | Blade width, articulation |

| Compactors | Soil and asphalt compaction | Drum width, vibration force |

Lifting Equipment

| Equipment | Primary Use | Key Specifications |

|---|---|---|

| Tower cranes | High-rise vertical movement | Height, jib length, tip load |

| Mobile cranes | Flexible heavy lifting | Lift capacity, boom length |

| Crawler cranes | Heavy lifts, rough terrain | Capacity, ground pressure |

| Telehandlers | Rough terrain material handling | Lift capacity, reach, height |

Critical Specifications

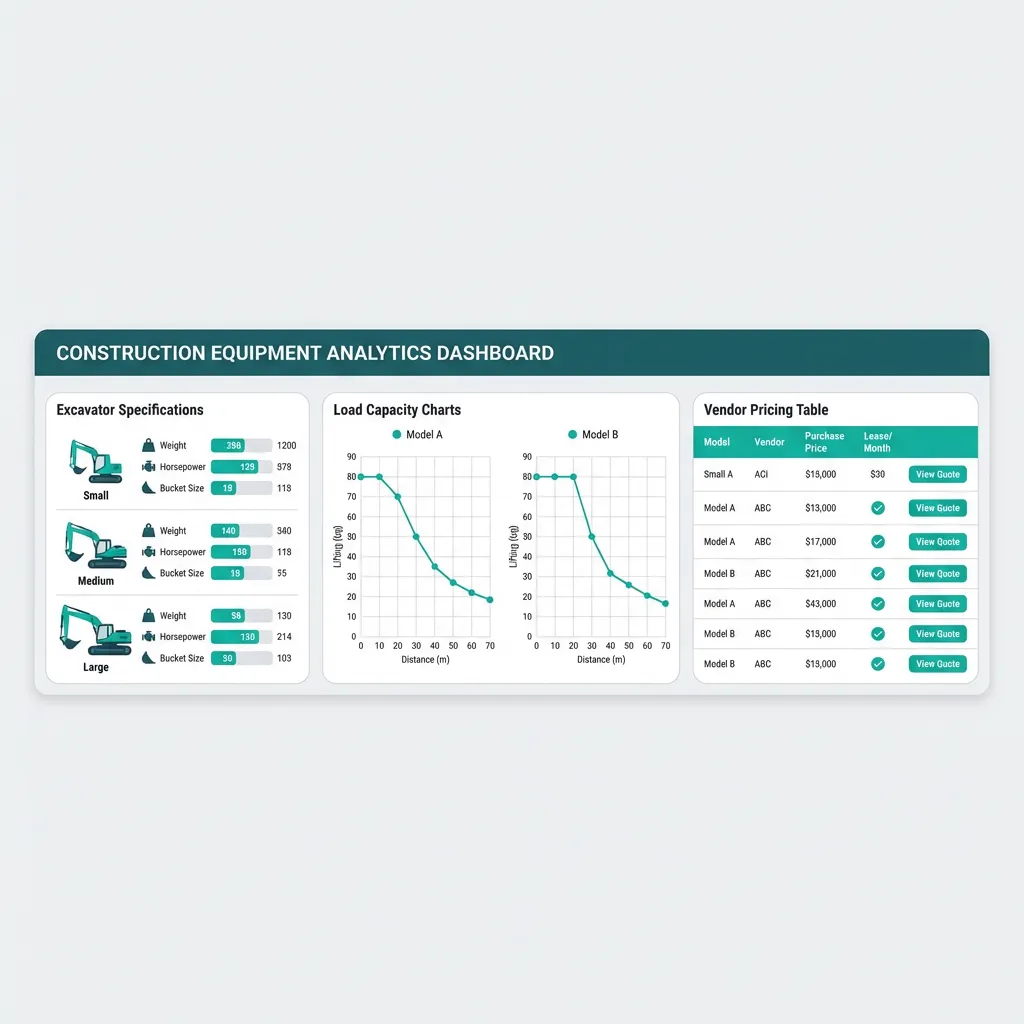

Excavator Specifications

| Specification | What It Means | Why It Matters |

|---|---|---|

| Operating weight | Total machine weight | Ground pressure, transport |

| Dig depth | Maximum excavation depth | Trench and foundation capability |

| Reach at ground | Horizontal reach | Working radius |

| Bucket capacity | Volume of bucket | Cycle productivity |

| Breakout force | Digging power | Material handling capability |

Crane Specifications

| Specification | What It Means | Why It Matters |

|---|---|---|

| Maximum capacity | Lift capacity at minimum radius | Heaviest pick possible |

| Capacity at radius | Lift at working distances | Actual job capability |

| Boom length | Maximum reach configuration | Working height and radius |

| Tip height | Maximum hook elevation | Building height capability |

Emissions & Compliance

| Regulation | Requirement | Impact |

|---|---|---|

| EPA Tier 4 Final | Current US emissions standard | Requires DEF, DPF, SCR |

| Stage V (EU) | European emissions standard | Similar to Tier 4 |

| CARB regulations | California-specific | More restrictive in some areas |

| Low-emission zones | Urban area restrictions | May limit equipment use |

Buy vs Rent Decision

When to Buy

| Factor | Buy Indicator |

|---|---|

| Utilization | High utilization expected (>60-70%) |

| Duration | Long-term need (years, not months) |

| Configuration | Specialized configuration required |

| Capability | Fleet management capability exists |

| Residual value | Strong expected resale |

When to Rent

| Factor | Rent Indicator |

|---|---|

| Utilization | Low or uncertain utilization |

| Duration | Short-term or project-specific need |

| Specialty | Equipment rarely needed |

| Cash | Cash preservation is priority |

| Flexibility | Need to scale fleet up/down |

Hybrid Arrangements

| Arrangement | Description | Best For |

|---|---|---|

| Rent-to-own | Rental payments apply toward purchase | Testing before committing |

| Operating lease | Set term, return equipment at end | Predictable cost |

| RPO | Rent with purchase option | Flexibility with potential ownership |

| Seasonal rental | Rent during peak, own core fleet | Variable demand |

Total Cost Analysis

| Category | Key Factors |

|---|---|

| Fuel | Consumption rate, hours, fuel prices |

| Maintenance | PM frequency, repair history, labor |

| Parts | Wear items, repair parts, filters |

| Insurance | Liability, physical damage |

| Operator | Labor cost, training |

Resale Value Factors

| Factor | Effect on Residual |

|---|---|

| Brand reputation | Premium brands hold value better |

| Condition | Maintenance history, appearance, wear |

| Hours | Primary depreciation driver |

| Configuration | Popular configurations sell faster |

Used vs. New Equipment

🔧 Buy NEW When:

- Reliability is paramount (primary crane, critical machine)

- Utilization is high (2,000+ hours/year)

- Technology matters (GPS grade control, telematics)

- You cannot risk undefined repair bills

⚙️ Buy USED When:

- It's a backup or support machine

- Going into harsh environment (demolition, rock crushing)

- Want to avoid 20-30% first-year depreciation

- Need equipment immediately (new lead times are 6 months)

Equipment Lifecycle

| Equipment Type | Typical Economic Life |

|---|---|

| Excavators | 10,000-15,000 hours |

| Loaders | 12,000-18,000 hours |

| Dozers | 12,000-18,000 hours |

| Trucks | 10,000-15,000 hours |

| Cranes | 15,000-25,000 hours |

Procurement Checklist

Requirements Definition

- ☐ Project requirements identified

- ☐ Equipment type and size determined

- ☐ Utilization estimate developed

- ☐ Buy vs rent analysis completed

- ☐ Budget established

Vendor Evaluation

- ☐ Potential sources identified

- ☐ Specifications collected

- ☐ Demonstrations/inspections completed

- ☐ References checked

- ☐ Dealer capabilities evaluated

Frequently Asked Questions

How do I evaluate used equipment?

Check hour meter history, maintenance records, physical condition (undercarriage, hydraulics, engine), and perform operational tests. Consider certified pre-owned programs with dealer warranty.

What's the general guideline for buy vs. rent?

If equipment will be used more than 60-70% of time over its lifecycle, buying often makes sense. For specialized or short-term needs, rental typically provides better value.

Compare Construction Equipment

SpecLens extracts and compares specifications from construction equipment vendors for systematic evaluation of excavators, cranes, and heavy machinery.

Compare Equipment Specs →Equip Your Projects Right

Construction equipment decisions affect project economics for years. Compare systematically and choose based on real project requirements, not marketing claims.

Tags:

Related Articles

Fleet Vehicle Procurement Guide

Master fleet vehicle procurement. Learn vehicle specs, TCO analysis, EV considerations, and comparison strategies for fleet purchasing.

Healthcare Equipment Procurement Guide

Master healthcare equipment procurement. Learn regulatory requirements, GPO considerations, and spec comparison for medical buyers.

IT Hardware Procurement Guide

Master IT hardware procurement. Learn server selection, storage evaluation, network specs, and vendor comparison strategies.

Manufacturing Equipment Buying Guide

Navigate manufacturing equipment procurement. Learn machinery specs, automation considerations, and vendor comparison strategies.