15 Hidden Procurement Costs

Discover hidden procurement costs that blow your budget. Learn to identify installation, training, maintenance, and overlooked expenses.

SpecLens Team

Procurement & AI Experts

Every procurement professional has experienced it—the moment you realize the real cost significantly exceeds the purchase price. Those "hidden" costs weren't really hidden; they just weren't asked about or included in the comparison.

This comprehensive guide exposes the most commonly overlooked procurement costs and shows you how to find them before they find your budget.

Why Hidden Costs Matter

Studies show the purchase price typically represents only 20-40% of total lifecycle costs.

The Comparison Impact

| Cost Element | Vendor A | Vendor B |

|---|---|---|

| Purchase price | $50,000 | $65,000 |

| Installation | $8,000 | Included |

| Training | $5,000 | $2,000 |

| 5-year maintenance | $30,000 | $17,500 |

| 5-Year TCO | $93,000 | $84,500 |

Key Insight: The "cheaper" vendor ($50K purchase) costs $8,500 more than the "expensive" vendor over 5 years.

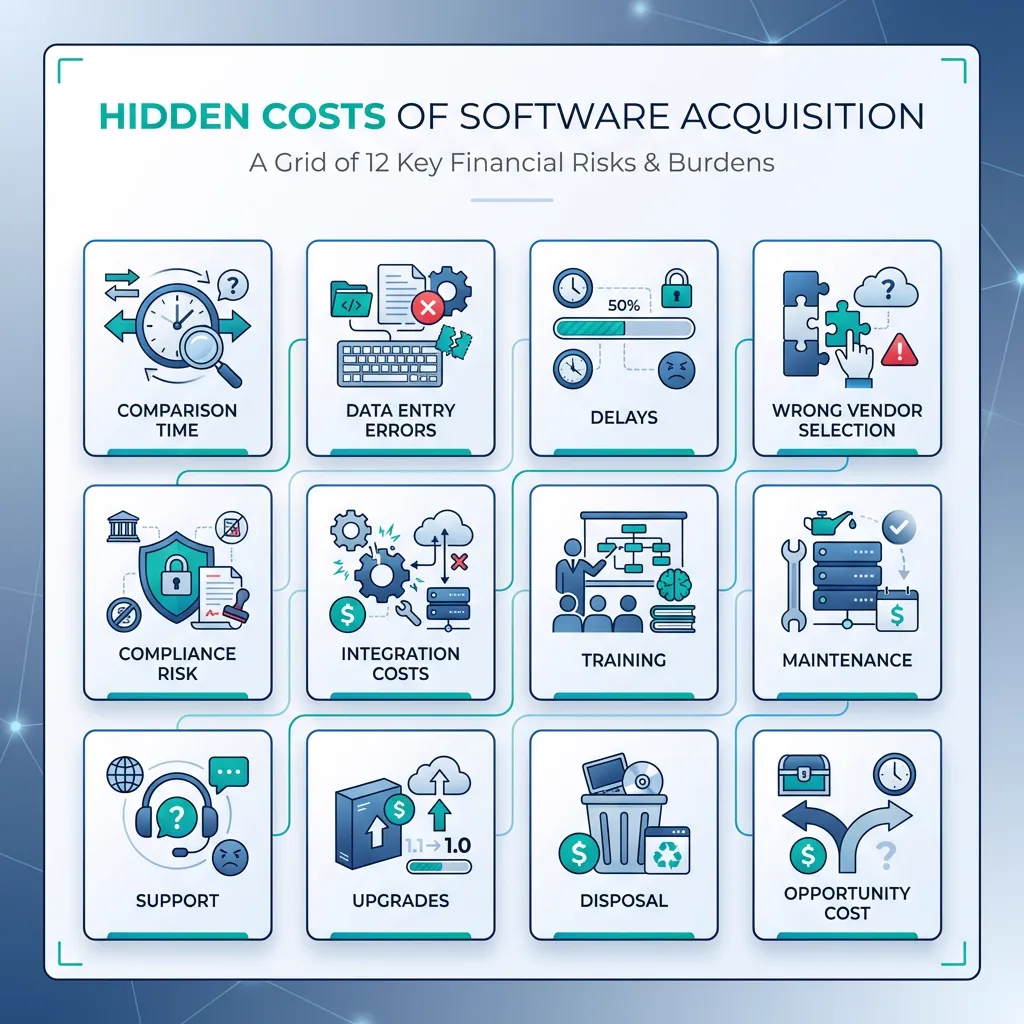

The 15 Hidden Cost Categories

1. Shipping and Logistics

| Cost Element | What to Ask |

|---|---|

| Freight | What's the delivery cost? |

| Insurance | Who covers transit damage? |

| Customs/duties | For international purchases |

| Special handling | Oversize, hazmat, delicate |

2. Installation and Setup

| Cost Element | What to Ask |

|---|---|

| Professional installation | Required or optional? |

| Site preparation | What must be ready? |

| Utilities connection | Power, water, network |

| Testing and commissioning | Startup validation |

3. Configuration and Customization

- Initial configuration setup time and cost

- Custom settings for non-standard configurations

- Feature activation licensing

- Integration setup with existing systems

4. Training

| Cost Element | What to Ask |

|---|---|

| User training | End-user education |

| Admin training | System management |

| Productivity loss | Learning curve period |

| Ongoing education | New features, refresh |

5. Maintenance and Support

| Cost Element | What to Ask |

|---|---|

| Warranty period | What's covered and for how long? |

| Post-warranty support | Annual maintenance cost (typically 10-15%) |

| Software updates | Included or additional? |

| Preventive maintenance | Scheduled service requirements |

6. Consumables and Supplies

- Regular consumables (filters, fluids, media)

- Wear parts that need replacement

- Proprietary supplies—must purchase from vendor?

- Supply frequency and inventory requirements

7. Energy and Utilities

⚡ Energy Cost Example

- Equipment draws 5 kW

- Operates 8 hours/day, 250 days/year

- 10,000 kWh/year × $0.12/kWh = $1,200/year

- Over 10 years: $12,000+

8-10. Facilities, Integration, Licensing

| Category | Key Questions |

|---|---|

| Space & Facilities | Floor space, HVAC modifications, electrical upgrades |

| Integration | API development, middleware, data migration |

| Licensing | Annual renewals, user tier changes, true-up audits |

11-15. Compliance, Disposal, and Other Costs

| Category | Considerations |

|---|---|

| Compliance | Certifications, ongoing audits, testing |

| Disposal | Equipment removal, recycling, data destruction |

| Opportunity Cost | What else could the money do? |

| Quality Costs | Rework, returns, warranty claims |

| Change Management | Productivity dip, process re-engineering |

Total Cost of Ownership Framework

| Phase | Cost Categories |

|---|---|

| Acquisition | Purchase price, shipping, installation, configuration |

| Implementation | Training, integration, migration, internal effort |

| Operations | Maintenance, support, consumables, energy, licensing |

| Transition | Disposal, migration, exit costs |

| Risk | Downtime, quality, contingency |

TCO Calculation Example

| Cost Category | Vendor A | Vendor B |

|---|---|---|

| Equipment | $50,000 | $65,000 |

| Shipping | $2,500 | Included |

| Installation | $8,000 | Included |

| Training | $5,000 | $2,000 |

| Integration | $3,000 | $1,500 |

| Maintenance (5yr) | $30,000 | $17,500 |

| Consumables (5yr) | $7,500 | $5,000 |

| Energy (5yr) | $6,000 | $4,500 |

| Risk Reserve | $5,000 | $3,000 |

| Total TCO | $121,000 | $101,000 |

📊 Result

Initial price difference: $15,000 higher for B

TCO difference: $20,000 lower for B

The "expensive" vendor is actually cheaper.

Finding Hidden Costs

| Question | What It Reveals |

|---|---|

| "What's not included in this price?" | Honest vendors will tell you |

| "What else will we need to purchase?" | Completeness of solution |

| "What does annual cost look like?" | Ongoing expenses |

| "What do similar customers spend?" | Real-world cost experience |

Frequently Asked Questions

How much do hidden costs typically add?

Depending on equipment type, hidden costs can add 60-150% to the purchase price over the equipment lifetime. Higher for complex, integrated systems.

How do we estimate internal costs?

Track staff hours on procurement activities, apply fully-loaded labor rates (salary × 1.3-1.5), include all departments involved, and add management oversight time.

What if vendors won't disclose all costs?

This is a red flag. Vendors should be transparent about what's included, additional items needed, and typical ongoing costs. Resistance suggests problems.

Build Complete TCO Analysis

Use our TCO calculator to systematically capture all costs and compare vendors on true total cost.

Build Complete TCO →See the Full Picture

Hidden costs aren't really hidden—they're just not asked about. Systematic TCO analysis ensures you're comparing total costs, not just purchase prices.

Tags:

Related Articles

Should-Cost Analysis Guide

Learn should-cost analysis methodology to understand fair market pricing. Build cost models to strengthen negotiation position and validate vendor proposals.

Free TCO Calculator + Complete Guide (2026)

Use our free TCO calculator to compare vendor costs. Includes the TCO formula, hidden cost checklist, and real industry examples.

Cloud vs On-Premise Software: 2026 Guide

Should you own your infrastructure or rent it? We breakdown the Cost, Security, and Scalability of Cloud vs On-Premise solutions.

The True Cost of Manual Procurement

Manual processes are bleeding your budget. We analyze the hidden costs of human error, slow processing, and employee burnout.