Spec Compliance Verification Guide

Learn how to verify vendor specs actually meet your requirements. Systematic compliance verification for accurate procurement.

SpecLens Team

Procurement & AI Experts

Vendors claim their products meet your requirements. But do they actually? Specification compliance verification is the systematic process of confirming that vendor specifications truly satisfy your stated needs—not just on paper, but in practice.

This comprehensive guide shows you how to verify compliance systematically, avoid common pitfalls, and ensure your procurement decisions are based on verified facts rather than vendor claims.

Why Specification Verification Matters

The Trust Gap

Vendor documentation serves multiple purposes, not all aligned with your interests:

| Vendor Purpose | Your Need |

|---|---|

| Sell products | Make informed decisions |

| Highlight strengths | Understand limitations |

| Differentiate from competitors | Compare objectively |

| Close deals | Minimize risk |

Key Insight: This gap means healthy skepticism is appropriate—and verification is essential.

The Cost of Assumption

| Assumption Risk | Potential Consequence |

|---|---|

| "Meets requirement" without proof | Equipment may not fit or function |

| Conditional specs not questioned | Fails under actual conditions |

| Marketing claims taken literally | Performance disappoints |

| Missing specs not flagged | Critical gaps discovered too late |

| Certifications not confirmed | Compliance issues emerge |

Common Compliance Failures

| Failure Type | Example | Impact |

|---|---|---|

| Borderline values | Spec says "up to 100 units"—you need 100 sustained | Capacity shortfall |

| Conditional specs | Meets spec "under ideal conditions" | Fails in real environment |

| Missing certifications | Claimed but not documented | Regulatory problems |

| Incompatible standards | Different edition of standard referenced | Integration failure |

| Configuration dependent | Base model doesn't include required capability | Additional cost |

| Terminology mismatch | Vendor "compliant" means something different | Expectation gap |

Types of Specifications to Verify

Mandatory vs. Desirable Specifications

| Type | Definition | Verification Level |

|---|---|---|

| Mandatory | Must be met for consideration | Full verification required |

| Desirable | Valued but not required | Verification based on materiality |

| Nice-to-have | Low priority | Minimal verification |

Technical Specifications

| Category | Examples | Verification Method |

|---|---|---|

| Physical | Dimensions, weight, power | Datasheet review, physical confirmation |

| Performance | Speed, capacity, throughput | Demonstration, third-party testing |

| Accuracy | Precision, tolerance, repeatability | Testing under specified conditions |

| Environmental | Operating temperature, humidity | Specification verification, testing |

Compliance Certifications

| Certification Type | Examples | Verification Method |

|---|---|---|

| Safety | UL, CE, CSA, TÜV | Certificate review, database check |

| Quality | ISO 9001, ISO 13485 | Certificate review, scope verification |

| Industry | FDA, HIPAA, PCI-DSS | Documentation review, audit reports |

| Environmental | RoHS, REACH, EPA | Declarations, test reports |

The Verification Process

Step 1: List Your Requirements

Create your requirements matrix:

| Spec ID | Requirement | Type | Acceptable Range | Evidence Required |

|---|---|---|---|---|

| PERF-001 | Throughput | M | ≥100 units/hour | Datasheet + demonstration |

| PHYS-003 | Operating temp | M | -20°C to +50°C | Datasheet |

| CERT-001 | CE marking | M | Valid certification | Certificate copy |

| COMPAT-002 | API integration | D | REST API available | Technical documentation |

Step 2: Extract Vendor Specifications

Create your verification matrix:

| Spec ID | Your Requirement | Vendor Claim | Source | Notes |

|---|---|---|---|---|

| PERF-001 | ≥100 units/hour | 120 units/hour | Datasheet p.3 | At standard conditions |

| PHYS-003 | -20°C to +50°C | 0°C to 45°C | Spec sheet p.2 | Below requirement |

| CERT-001 | CE marking | CE certified | Proposal p.8 | Need certificate |

| COMPAT-002 | REST API | "API available" | Brochure p.4 | Need documentation |

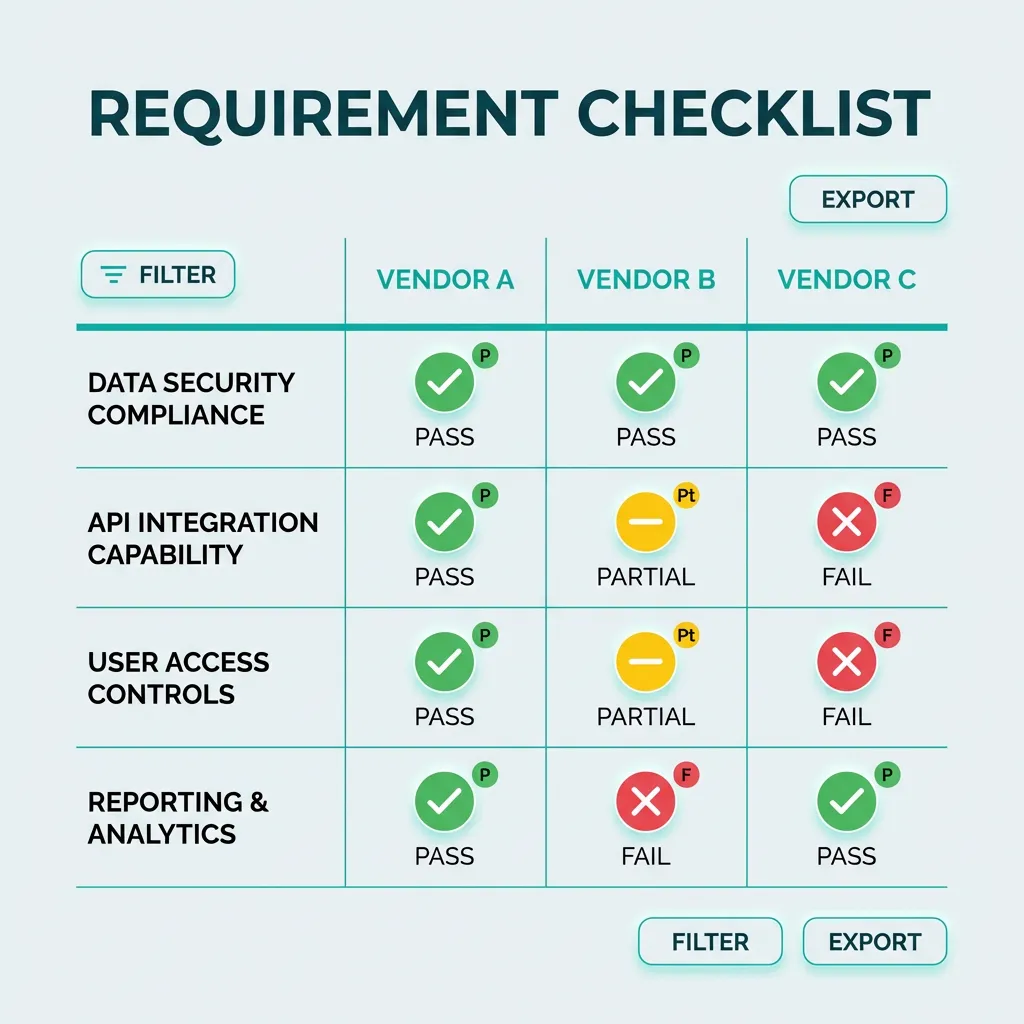

Step 3: Compare and Classify

| Status | Symbol | Meaning | Action |

|---|---|---|---|

| Compliant | ✓ | Meets or exceeds requirement | Proceed |

| Partial | △ | Close but not exact | Clarify, evaluate risk |

| Non-compliant | ✗ | Does not meet | Flag for decision |

| Not addressed | ○ | No vendor response | Request clarification |

| Unable to verify | ? | Insufficient evidence | Request documentation |

Step 4: Investigate Discrepancies

For anything not fully compliant:

- Request clarification: Formal written request with deadline

- Seek additional evidence: Third-party test reports, customer references, demonstrations

- Evaluate risk: Probability of problem, impact, mitigation options

Step 5: Document Everything

Create complete verification audit trail for each specification:

- Original requirement and rationale

- Vendor's stated specification

- Source document and location

- Verification method used

- Evidence reviewed

- Compliance determination

- Decision rationale

- Residual risk (if any)

Common Verification Challenges

Terminology Differences

| You Say | Vendor May Say |

|---|---|

| Power consumption | Electrical draw, rated wattage, power demand |

| Operating temperature | Ambient temp range, environmental limits |

| Data transfer rate | Throughput, bandwidth, link speed |

| Accuracy | Precision, tolerance, error margin |

| Response time | Latency, delay, processing time |

Conditional Specifications

| Condition Type | Example | Risk |

|---|---|---|

| Environmental | "At sea level" / "at 25°C" | Your environment differs |

| Operational | "Maximum" vs. "continuous" | You need sustained performance |

| Configuration | "With option X" | Option not included |

| Load | "At rated capacity" | Your load pattern differs |

| Test conditions | "Under laboratory conditions" | Real world differs |

Vague or Qualitative Claims

| Vague Claim | What You Need |

|---|---|

| "High performance" | Specific performance metric |

| "Energy efficient" | Efficiency rating or consumption data |

| "Industry standard" | Specific standard reference |

| "Fast processing" | Processing time specification |

| "Reliable" | MTBF, warranty terms, field data |

Third-Party Verification Services

🔬 When to Use a Lab

- Material Properties: Steel hardness, chemical composition

- Safety Critical: Fire rating, electrical safety

- High Volume: Testing one to destruction is cheap insurance for 10,000 units

Cost vs. Risk: Spending $2,000 on a lab test is a bargain if it prevents a $1M recall.

The Cost of Non-Verification

- Recall Costs: Average recall costs $10M+

- Downtime: If the "verified" motor fails, production stops for 3 days

- Safety: An unverified pressure vessel is a bomb

Takeaway: Verification is not an expense; it is a safety shield.

Verification Checklist

Preparation

- ☐ Requirements list complete with all specifications

- ☐ Each requirement marked mandatory (M) or desirable (D)

- ☐ Acceptable ranges/values defined

- ☐ Evidence requirements specified

- ☐ Verification matrix template ready

Extraction

- ☐ Current vendor documentation obtained

- ☐ Vendor specifications located for each requirement

- ☐ Values extracted accurately with units

- ☐ Source locations documented (document, page)

- ☐ Measurement conditions noted

Comparison

- ☐ Units normalized across all vendors

- ☐ Terminology mapped to common terms

- ☐ Values compared to requirements

- ☐ Compliance status assigned for each spec

- ☐ Gaps and non-compliance flagged

Validation

- ☐ Non-compliant items investigated

- ☐ Clarification requests issued

- ☐ Additional evidence requested where needed

- ☐ Risk assessment completed for remaining gaps

- ☐ Compliance decisions documented

Frequently Asked Questions

How much verification is enough?

- Minimum: Verify all mandatory requirements completely

- Reasonable: Verify mandatory fully; sample verify desirables based on risk

- Thorough: Verify everything for high-risk or high-value procurements

What if vendor won't provide documentation?

Reluctance to document is itself a red flag. May indicate inability to support claims, poor quality, or predict future support problems. Consider whether you want to do business with vendors who won't support their claims.

Can we rely on vendor self-certification?

| Risk Level | Reliance Appropriate |

|---|---|

| Low risk, non-critical | Vendor claims acceptable |

| Moderate risk | Require documentation |

| High risk, critical | Independent verification |

How do we handle specifications we can't verify pre-purchase?

Protect yourself contractually:

- Require vendor to warrant specification compliance

- Include acceptance testing provisions

- Define remedies for non-compliance

- Allow rejection for material specification failures

Verify Specifications Automatically

SpecLens extracts specifications from vendor documents and flags gaps against your requirements automatically, saving hours of manual verification.

Try Automated Verification →Verify Before You Buy

Specification compliance verification protects your organization from vendor claims that don't match reality. The time invested in systematic verification is minimal compared to the cost of discovering non-compliance after purchase.

Download Verification Template → | Specification Gap Analysis →

Tags:

Related Articles

Unit Conversion in Procurement

Master unit conversion in procurement to avoid spec mismatches and costly errors. Includes conversion tables and formulas.

Specification Gap Analysis Guide

Learn specification gap analysis to identify missing vendor information. Catch incomplete proposals before they become costly.

Technical Spec Sheet Analysis

Master technical spec sheet analysis for procurement. Extract critical specs, spot gaps, and compare vendor datasheets.

Vendor Datasheet Comparison Methods

Learn effective vendor datasheet comparison methods. Transform PDF datasheets into structured side-by-side comparisons.