Technical Spec Sheet Analysis

Master technical spec sheet analysis for procurement. Extract critical specs, spot gaps, and compare vendor datasheets.

SpecLens Team

Procurement & AI Experts

A technical spec sheet contains the truth about what equipment can and can't do—but only if you know how to read it. Marketing claims disappear when you examine the actual specifications. The best vendor becomes obvious when you compare what matters.

This comprehensive guide teaches you how to analyze technical spec sheets for effective procurement decisions.

Why Spec Sheet Analysis Matters

Beyond Marketing Claims

Spec sheets provide objective data:

| Marketing Says | Spec Sheet Shows |

|---|---|

| "High performance" | Actual throughput numbers |

| "Energy efficient" | Power consumption in watts |

| "Compact design" | Exact dimensions |

| "Industry-leading" | Measurable specifications |

| "Easy integration" | Interface specifications |

The Decision Foundation

| Capability | Result |

|---|---|

| Objective comparison | Data-driven vendor selection |

| Requirements verification | Confirm fit to needs |

| Gap identification | Know what's missing |

| Future planning | Assess scalability |

| Risk reduction | Avoid capability surprises |

Common Spec Sheet Challenges

| Challenge | Impact |

|---|---|

| Different formats | Hard to compare directly |

| Varying terminology | Same spec, different names |

| Unit inconsistencies | Conversions required |

| Missing specifications | Gaps not obvious |

| Conditional claims | Footnotes limit applicability |

| Marketing mixed in | Separating substance from spin |

Understanding Spec Sheet Structure

Common Sections

| Section | Contains |

|---|---|

| Overview | Product summary, key features |

| Performance | Speed, capacity, throughput |

| Physical | Dimensions, weight, mounting |

| Electrical | Power, voltage, current |

| Environmental | Temperature, humidity, rating |

| Interface | Connectivity, protocols, compatibility |

| Compliance | Certifications, standards |

Reading Priority

| Priority | Focus |

|---|---|

| Critical | Specifications that determine fit-for-purpose |

| Important | Specifications affecting value and efficiency |

| Reference | Specifications unlikely to differentiate |

| Ignore | Marketing claims without technical substance |

Understanding Values and Conditions

Specifications often come with conditions:

| Specification Statement | What It Actually Means |

|---|---|

| "Up to 1000 units/hour" | Maximum under ideal conditions |

| "Operating temp: 0-40°C" | Won't work outside this range |

| "99.9% uptime (typical)" | Not guaranteed |

| "*See footnote" | Limitations apply |

Pro Tip: Always read the conditions attached to specifications. The headline number is often the best-case scenario, not the typical performance.

Critical Specification Categories

Performance Specifications

These determine if equipment can do the job:

| Specification Type | Examples | Why It Matters |

|---|---|---|

| Capacity | Volume, units, throughput | Can it handle your needs? |

| Speed | Cycle time, processing rate | Fast enough for requirements? |

| Accuracy | Precision, tolerance, error rate | Quality level acceptable? |

| Power | Horsepower, wattage, torque | Sufficient for application? |

| Range | Operating range, coverage | Works in your conditions? |

Physical Specifications

Determine if equipment fits your environment:

| Specification Type | Examples | Why It Matters |

|---|---|---|

| Dimensions | Length, width, height | Fits in allocated space? |

| Weight | Operating weight, shipping weight | Floor load, handling capacity? |

| Mounting | Floor, rack, wall, etc. | Compatible with installation? |

| Footprint | Floor space required | Space efficient? |

| Clearance | Service access requirements | Room for maintenance? |

Common oversights:

- Forgetting service clearance requirements

- Not checking floor load capacity

- Ignoring door/elevator size for installation

- Missing utility connection locations

Electrical Specifications

| Specification Type | Examples | Why It Matters |

|---|---|---|

| Voltage | 120V, 208V, 240V, 480V | Match available power? |

| Phase | Single-phase, 3-phase | Electrical infrastructure? |

| Current | Amps, full-load amps | Circuit capacity? |

| Power | Watts, kW | Operating cost, capacity? |

| Efficiency | 80 PLUS rating, efficiency % | Energy cost? |

Environmental Specifications

| Specification Type | Examples | Why It Matters |

|---|---|---|

| Temperature | Operating range, storage range | Works in your environment? |

| Humidity | RH range, condensing limits | Climate appropriate? |

| Altitude | Maximum operating altitude | High-altitude locations? |

| IP rating | Ingress protection (dust/water) | Environmental exposure? |

| Vibration | Tolerance levels | Installation environment? |

⚠️ Temperature Example

- Equipment operating range: 0°C to 40°C

- Your environment: Warehouse with summer peaks of 45°C

- Problem: Equipment may not perform or survive

Interface Specifications

| Specification Type | Examples | Why It Matters |

|---|---|---|

| Physical ports | USB, Ethernet, serial, etc. | Connection capability? |

| Protocols | MODBUS, OPC-UA, REST API | System integration? |

| Data formats | JSON, XML, CSV | Data exchange? |

| Standards compliance | Industry protocols | Interoperability? |

| Expansion | Slots, ports, capacity | Future growth? |

Compliance Specifications

| Specification Type | Examples | Why It Matters |

|---|---|---|

| Safety certifications | UL, CE, CSA | Legal requirements? |

| Industry standards | ISO, ASME, ASTM | Quality assurance? |

| Regulatory approval | FDA, FCC, EPA | Permitted use? |

| Environmental | RoHS, WEEE | Sustainability compliance? |

Extraction Methodology

Step 1: Prepare Your Requirements List

| Requirement ID | Specification | Required Value | Priority |

|---|---|---|---|

| REQ-001 | Processing speed | ≥ 500 units/hour | Critical |

| REQ-002 | Power supply | 208V single-phase | Critical |

| REQ-003 | Operating temp | -10°C to 45°C | Important |

| REQ-004 | Network interface | Ethernet, REST API | Important |

Step 2: Extract Systematically

- Find the corresponding specification

- Note the exact value

- Note the units

- Note any conditions

- Record page/section reference

Step 3: Normalize Data

| Vendor | Raw Value | Normalized |

|---|---|---|

| A | 500 units/hr | 500 units/hr |

| B | 9 units/min | 540 units/hr |

| C | 0.15 units/sec | 540 units/hr |

Step 4: Compare to Requirements

| Requirement | Required | Vendor A | Vendor B | Vendor C |

|---|---|---|---|---|

| Speed | ≥ 500 u/hr | 500 ✓ | 540 ✓ | 540 ✓ |

| Voltage | 208V | 208V ✓ | 480V ✗ | 208V ✓ |

| Temp range | -10 to 45°C | 0-40°C ✗ | -20 to 50°C ✓ | -10 to 45°C ✓ |

Common Analysis Pitfalls

Assuming Unmarked = Adequate

Mistake: If a specification isn't listed, assuming it's acceptable.

Reality: Missing specifications may mean not applicable, vendor doesn't know, deliberately omitting unfavorable data, or different terminology.

Solution: Ask directly when critical specifications are missing.

Ignoring Conditions and Footnotes

Mistake: Reading headline numbers, skipping fine print.

Example:

Headline: "1000 units/hour capacity"

Footnote: "*At 50% of rated load"

Solution: Always read conditions. Understand what's really being specified.

Comparing Incomparable Values

Mistake: Comparing values measured differently.

Example:

- Vendor A: "Efficiency: 95%" (at full load)

- Vendor B: "Efficiency: 92%" (across operating range)

Solution: Understand measurement conditions. Request comparable data.

Standardizing Units: The Metric Headache

Nothing kills a comparison faster than mixed units.

📐 The "Bar vs PSI" Problem

- Vendor A: 10 Bar

- Vendor B: 150 PSI

Quick check: 10 Bar = 145 PSI. Vendor B wins.

Without converting, Vendor A looks smaller ("10" < "150").

Best Practice: Create a "Normalized" column in your analysis spreadsheet. Convert EVERYTHING to your standard unit.

Handling "Proprietary" Values

Vendors love to invent metrics that only they can win.

- Apple: "Retina Display" (Instead of PPI)

- Dyson: "Air Watts" (Instead of CFM/Suction)

The Procurement Counter-Move: Reject the proprietary unit. Ask for the underlying scientific metric. If they refuse, penalize the score for "Lack of Transparency."

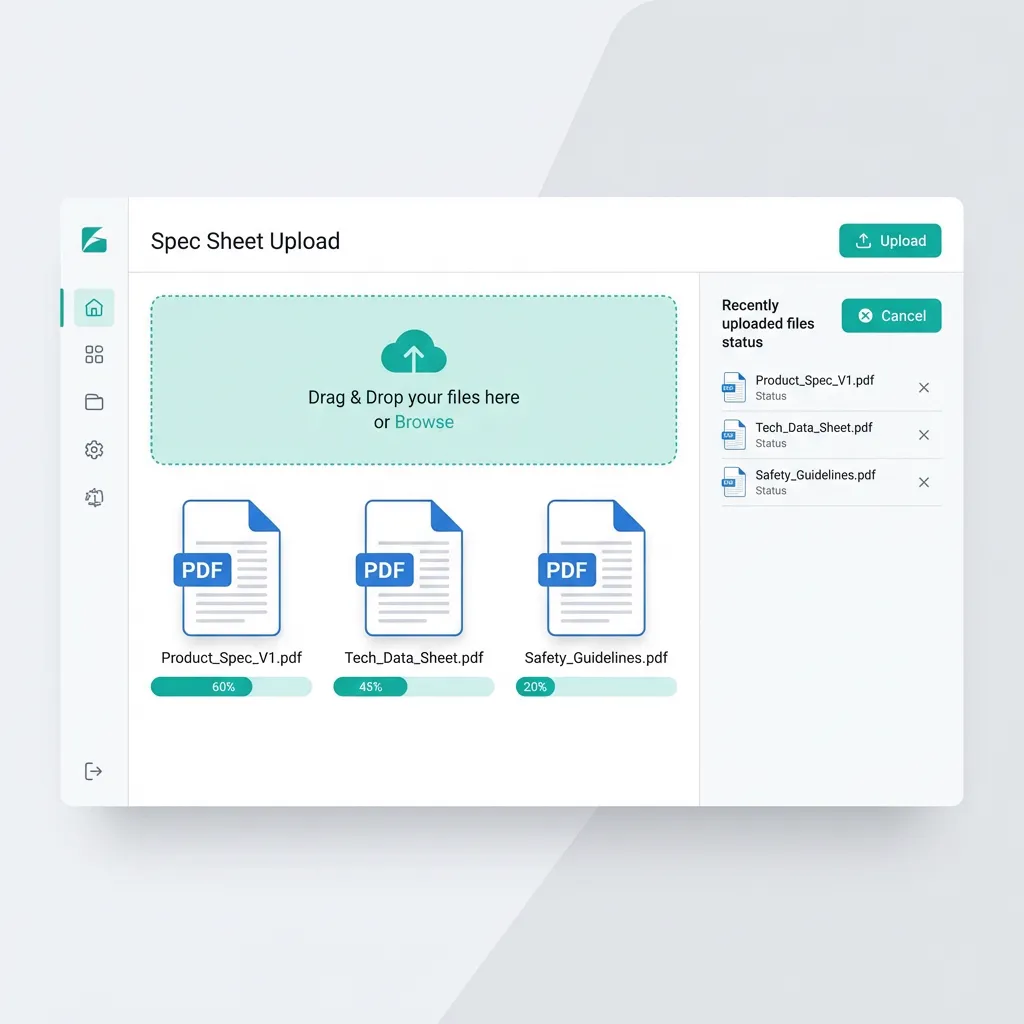

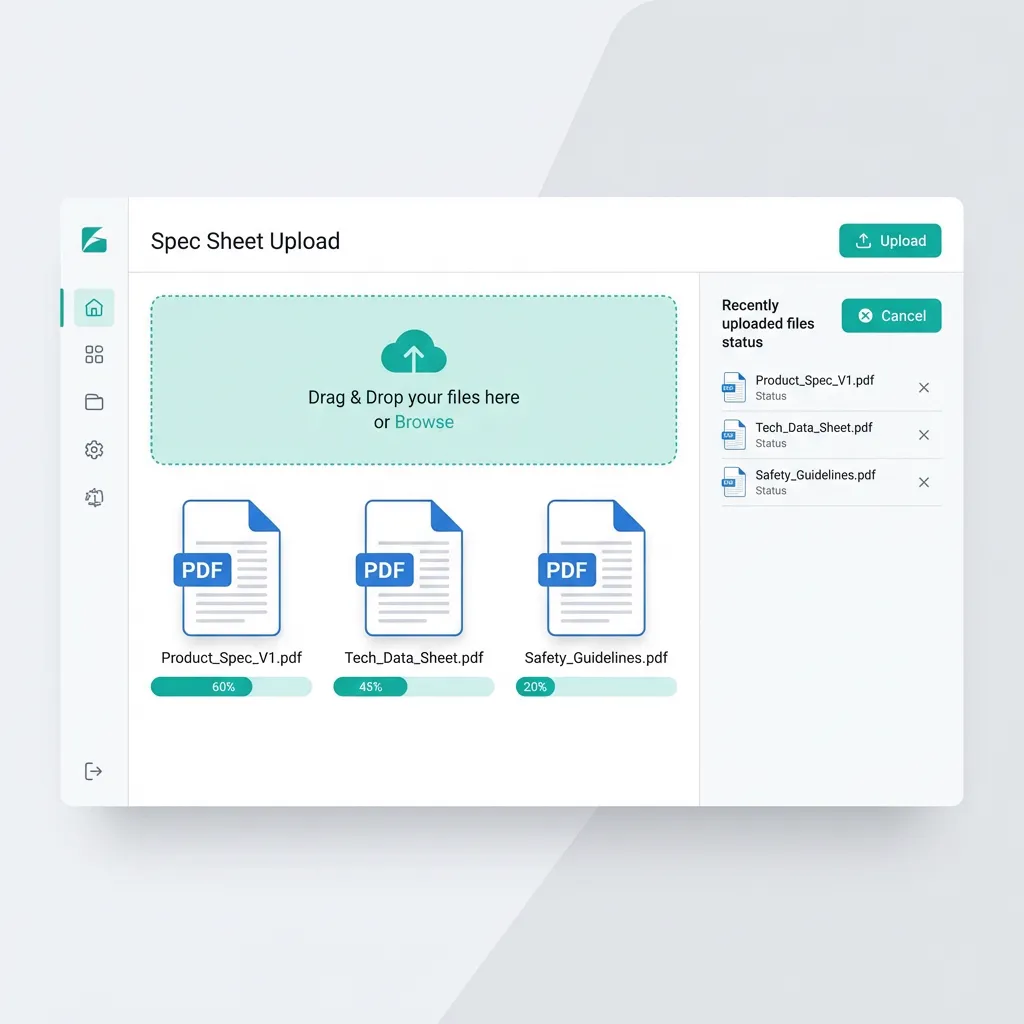

AI-Powered Spec Sheet Analysis

| Task | Manual | AI-Powered |

|---|---|---|

| Extract specifications | Hours per vendor | Minutes total |

| Normalize units | Manual calculation | Automatic |

| Terminology mapping | Experience required | AI handles |

| Gap detection | Visual inspection | Automatic highlighting |

| Comparison matrix | Build spreadsheet | Auto-generated |

Spec Sheet Analysis Checklist

Before Analysis

- ☐ Requirements list prepared

- ☐ Priority specifications identified

- ☐ Unit preferences established

- ☐ Comparison framework ready

During Analysis

- ☐ All required specifications extracted

- ☐ Units recorded with values

- ☐ Conditions and footnotes noted

- ☐ Source locations documented

- ☐ Missing specifications flagged

After Analysis

- ☐ Values normalized for comparison

- ☐ Requirements compliance checked

- ☐ Gaps identified and documented

- ☐ Questions for vendors listed

- ☐ Summary prepared for decision-makers

Frequently Asked Questions

How do I handle conflicting specifications?

When vendors report different values for the same specification, check measurement conditions, verify test standards used, request clarification, and use the conservative value for planning.

Should I verify spec sheet accuracy?

For critical specifications, yes. Request test data, check with references, conduct demonstrations, and include performance guarantees in contract.

What if all vendors are missing the same specification?

This may indicate the specification isn't standard for this product type, your requirement is unusual, the industry uses different terminology, or the specification needs to be requested from all vendors.

How detailed should spec analysis be?

- Commodity: Focus on critical specs only

- Significant purchase: Thorough analysis of all relevant specs

- Strategic: Deep analysis plus validation

Analyze Spec Sheets Faster with AI

SpecLens extracts specifications from technical documents automatically, normalizes units, and creates comparison-ready matrices in minutes instead of hours.

Try AI Spec Analysis →Master Specification Analysis

Effective spec sheet analysis separates the best vendors from the rest. Whether analyzing manually or using AI tools, a structured approach ensures complete, accurate, comparable data for procurement decisions.

Download Analysis Template → | Vendor Datasheet Comparison →

Tags:

Related Articles

Vendor Datasheet Comparison Methods

Learn effective vendor datasheet comparison methods. Transform PDF datasheets into structured side-by-side comparisons.

Spec Compliance Verification Guide

Learn how to verify vendor specs actually meet your requirements. Systematic compliance verification for accurate procurement.

Specification Gap Analysis Guide

Learn specification gap analysis to identify missing vendor information. Catch incomplete proposals before they become costly.

Unit Conversion in Procurement

Master unit conversion in procurement to avoid spec mismatches and costly errors. Includes conversion tables and formulas.