Vendor Datasheet Comparison Methods

Learn effective vendor datasheet comparison methods. Transform PDF datasheets into structured side-by-side comparisons.

SpecLens Team

Procurement & AI Experts

You have datasheets from five vendors. Each uses different formats, terminology, and units. Comparing them means hours of manual work—and the risk of missing critical differences.

Effective datasheet comparison is essential for objective vendor selection. This comprehensive guide shows you how to transform scattered PDFs into structured side-by-side analysis.

The Datasheet Comparison Challenge

What You're Dealing With

| Variation | Example |

|---|---|

| Format | PDFs, web pages, Excel, print brochures |

| Structure | Different section orders, varying completeness |

| Terminology | Same spec, different names |

| Units | Inches vs. millimeters, PSI vs. bar |

| Presentation | Marketing emphasis vs. technical detail |

| Completeness | Some specs present, others missing |

Why Comparison Is Difficult

| Challenge | Impact |

|---|---|

| Different formats | Can't overlay or directly compare |

| Terminology variations | Same thing called different names |

| Missing specifications | What's not stated may matter |

| Unit differences | Can't compare without conversion |

| Marketing spin | Claims without supporting data |

| Hidden footnotes | Conditions that limit specifications |

The Cost of Poor Comparison

| Consequence | Impact |

|---|---|

| Wrong vendor selected | Doesn't meet actual requirements |

| Hidden gaps discovered late | Post-purchase problems |

| Overpaying | Better options not identified |

| Analysis paralysis | Delayed decisions from complexity |

| Inconsistent evaluation | Unfair to some vendors |

Manual Comparison Approach

Step 1: Create Specification List

Before reviewing datasheets, establish what you need to compare:

| Spec Category | Specifications to Compare |

|---|---|

| Physical | Dimensions, weight, mounting, footprint |

| Performance | Speed, capacity, accuracy, throughput |

| Electrical | Power, voltage, current, phase |

| Environmental | Temperature, humidity, IP rating, altitude |

| Compatibility | Interfaces, standards, protocols, connectors |

| Compliance | Certifications, regulatory approvals |

Pro Tip: Start with your requirements, not vendor datasheets. This ensures you're comparing what matters for your application.

Step 2: Create Comparison Matrix

Set up a standardized template with these elements:

- Specification name (exactly as defined in requirements)

- Unit of measurement (standardized)

- Your requirement value (threshold to meet)

- Vendor columns (one per vendor)

- Notes column (for conditions, clarifications)

- Source reference (page and section)

Step 3: Extract from Each Datasheet

- Open datasheet

- For each specification on your list, find the value (if present)

- Note the page/section and record exactly as stated

- Note units and flag if missing

- Document any conditions or footnotes

Step 4: Normalize Data

Convert all values to common units:

| Raw Data | Normalized |

|---|---|

| 1 inch | 25.4 mm |

| 120 PSI | 8.27 bar |

| 77°F | 25°C |

| 10 HP | 7.457 kW |

| 100 lb | 45.36 kg |

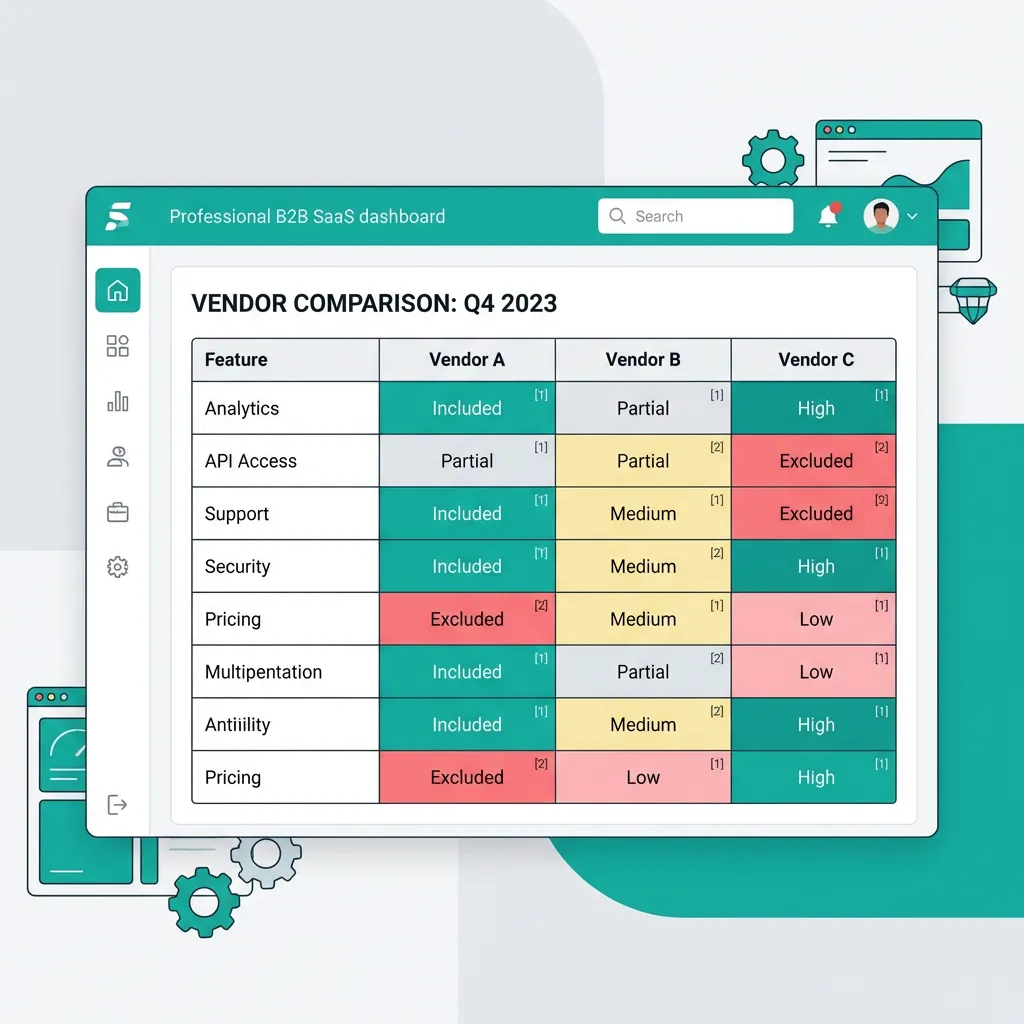

Step 5: Compare and Highlight

| Condition | Highlighting |

|---|---|

| Meets requirement | Green |

| Exceeds requirement | Blue |

| Close to requirement | Yellow |

| Below requirement | Red |

| Missing data | Orange |

Time Required

| Vendors | Specifications | Estimated Time |

|---|---|---|

| 3 | 20 | 3-5 hours |

| 5 | 30 | 6-10 hours |

| 10 | 50 | 15-25 hours |

AI-Powered Comparison Approach

How AI Accelerates Comparison

| Manual Step | AI Automation |

|---|---|

| Extract from each datasheet | Automatic extraction |

| Create comparison matrix | Auto-generated |

| Normalize units | Automatic conversion |

| Map terminology | Term normalization |

| Identify gaps | Automatic gap detection |

| Highlight differences | Visual comparison |

AI Advantages for Comparison

| Advantage | Benefit |

|---|---|

| Speed | Hours become minutes |

| Consistency | Same extraction every time |

| Completeness | Doesn't get tired or skip sections |

| Scalability | Handle more vendors without proportional time |

| Normalization | Automatic unit conversion |

| Terminology mapping | Understands synonyms |

Time Comparison

| Approach | 5 Vendors × 30 Specs |

|---|---|

| Manual | 6-10 hours |

| AI-assisted | 30-60 minutes |

| Savings | 85-90% |

Building Effective Comparison Matrices

Matrix Structure

| Component | Purpose |

|---|---|

| Specification rows | One row per specification |

| Category grouping | Related specs together |

| Requirement column | Your stated requirement |

| Vendor columns | One per vendor |

| Source reference | Page/section citation |

| Notes column | Conditions, clarifications |

| Compliance indicator | Pass/fail/partial |

Handling Missing Data

| Approach | When to Use |

|---|---|

| Contact vendor | Critical specifications |

| Mark as missing | Document the gap |

| Estimate/research | If industry standards apply |

| Disqualify | If mandatory and not addressed |

| Request demo | Verify through testing |

Common Comparison Mistakes

Comparing Marketing Claims

Problem: Taking marketing statements as specifications.

- "Industry-leading performance" ≠ actual performance metric

- "High efficiency" ≠ efficiency percentage

- "Easy to install" ≠ installation time or requirements

Solution: Compare only quantifiable specifications with units and values.

Ignoring Conditions

Example:

"100 units/hour*" (*under ideal conditions)

"Operating range: -20°C to 50°C (storage), -10°C to 40°C (operating)"

Solution: Read footnotes carefully; document conditions. Compare on the same basis.

Assuming Missing = Zero

Problem: Treating unaddressed specifications as failures.

Reality: May have the specification but didn't include in summary datasheet.

Solution: Request clarification before concluding. Don't penalize for documentation gaps without verification.

The "Apples to Oranges" Problem

📊 Bundle vs. Components

What if Vendor A sells a "System" and Vendor B sells "Components"?

The Solution: Deconstruct to compare. Take Vendor B's base unit + required options + integration labor = "Virtual System."

Never compare a partial solution to a turnkey solution without adjusting.

From Comparison to Decision

Scoring Based on Comparison

| Comparison Result | Suggested Score |

|---|---|

| Exceeds requirement significantly | 5 |

| Exceeds requirement | 4 |

| Meets requirement | 3 |

| Close to requirement | 2 |

| Below requirement | 1 |

| Missing/non-compliant | 0 |

Weighting Specifications

| Weight Level | Apply When |

|---|---|

| High (1.5x) | Specification is critical to function |

| Standard (1.0x) | Normal importance |

| Low (0.5x) | Nice-to-have specification |

| Mandatory | Must be met (pass/fail) |

Industry-Specific Considerations

Manufacturing Equipment

| Focus Areas | Why |

|---|---|

| Tolerances | Production quality |

| Cycle times | Throughput |

| Tooling compatibility | Integration with existing |

| Maintenance access | Ongoing operation |

IT Hardware

| Focus Areas | Why |

|---|---|

| Compatibility standards | Integration |

| Scalability | Future growth |

| Power/cooling | Data center capacity |

| Management interfaces | Operations |

Frequently Asked Questions

How many specifications should we compare?

- Minimum: All mandatory requirements

- Recommended: 20-50 key specifications

- Maximum: Diminishing returns beyond 50-75

What if vendors use different test methods?

Document the test method with each specification. Where methods differ significantly, specifications may not be directly comparable. Note this in your analysis.

Should we share our comparison matrix with vendors?

Generally no before selection—this reveals your requirements weighting. After selection, sharing may help with clarifications and negotiations.

How do we verify datasheet accuracy?

| Verification Method | When to Use |

|---|---|

| Demonstration | Before procurement |

| Reference checking | Always for significant purchases |

| Third-party testing | Critical specifications |

| Contractual guarantees | Include in contract |

| Site visits | For major equipment |

Compare Datasheets Automatically

SpecLens extracts specifications from any vendor document, normalizes units and terminology, and creates side-by-side comparison matrices in minutes.

Try AI Comparison →Transform Your Comparison Process

Vendor datasheet comparison doesn't have to consume hours of manual effort. Structured process—whether manual or AI-assisted—enables objective, thorough vendor evaluation.

Download Comparison Template → | Spec Sheet Analysis Guide →

Tags:

Related Articles

Technical Spec Sheet Analysis

Master technical spec sheet analysis for procurement. Extract critical specs, spot gaps, and compare vendor datasheets.

Spec Compliance Verification Guide

Learn how to verify vendor specs actually meet your requirements. Systematic compliance verification for accurate procurement.

Specification Gap Analysis Guide

Learn specification gap analysis to identify missing vendor information. Catch incomplete proposals before they become costly.

Unit Conversion in Procurement

Master unit conversion in procurement to avoid spec mismatches and costly errors. Includes conversion tables and formulas.